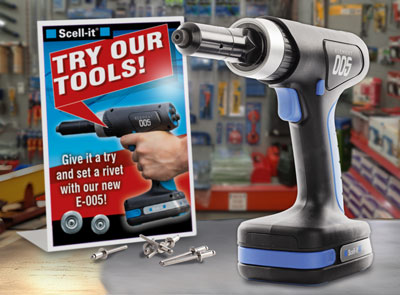

Chemical Anchors and how to install them.

What are chemical anchors?

Chemical anchors refer to bonding used between metallic elements (steel studs, bolts and anchorages) and substrate materials (usually masonry or concrete) using a resin based adhesive system.

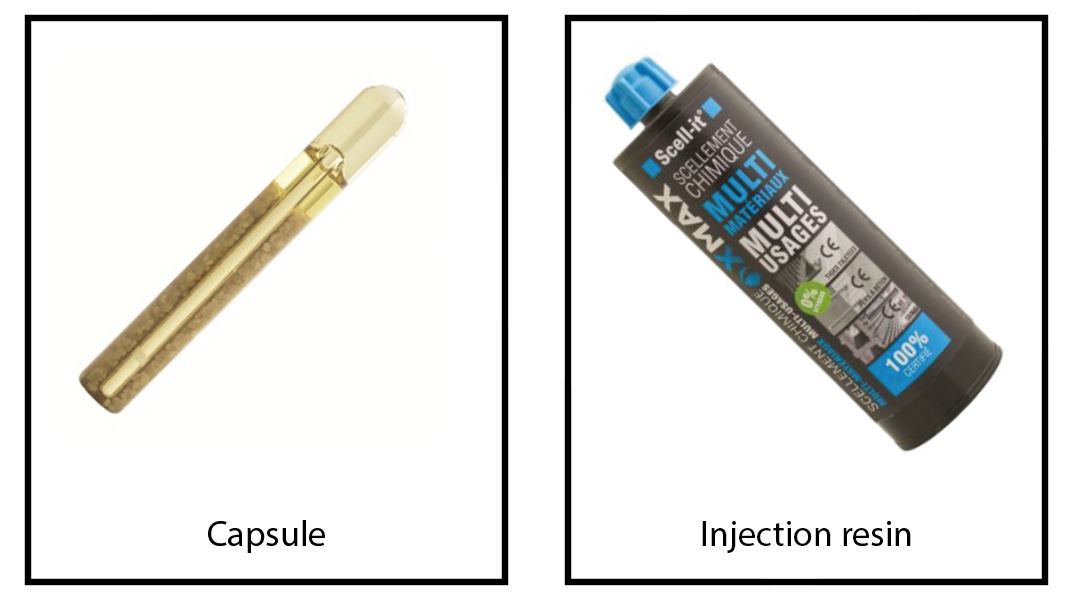

There are two types of chemical anchor systems: injection and capsule. Spin-in chemical capsule or hammer-in are very common for general anchoring – but the strength is less than injection cartridge adhesive anchoring and size is limited.

This guide is looking at the injection type system which is much stronger and forms very strong bonds which are actually stronger than the base material.

Chemical adhesion is used to create these strong bonds which means that the base material does not get any load stress and are therefore ideal for close to edge fixing, reduced centre and group anchoring and use in the concrete of unknown quality or low compressive strength.

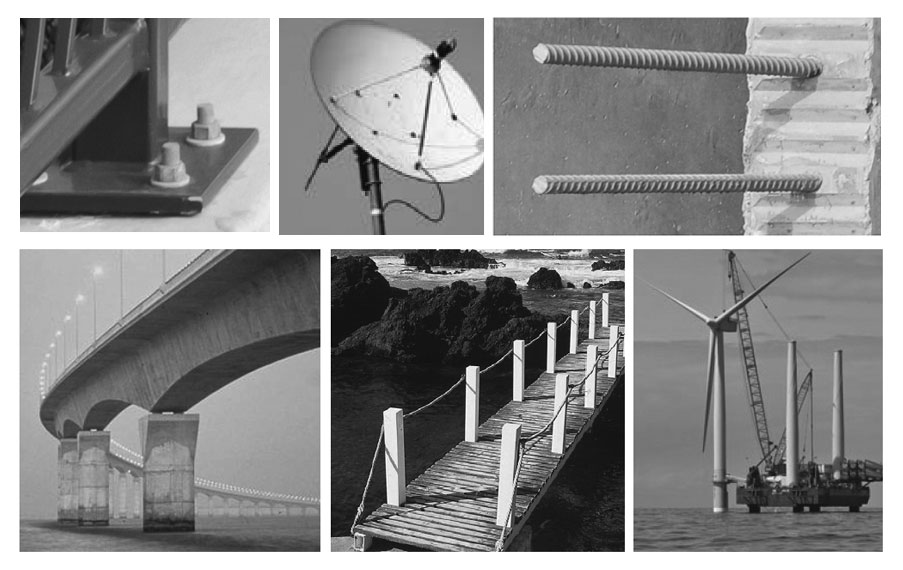

This means they are highly effective when used in high load applications and has made them a more popular option than expansion anchors.

How are chemical anchors applied?

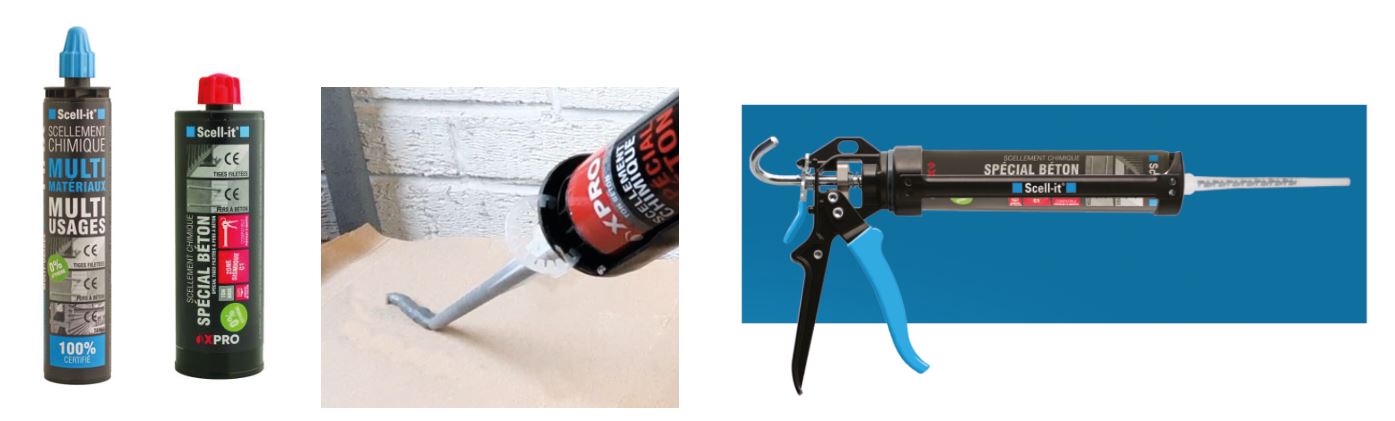

All injection chemical anchor systems operate using the same basic principle: the base resin mixes with a second component (a hardener) to begin the chemical curing process and achieve a strong bond. A resign injection gun (or caulking gun) is used to squeeze out and mix the two components which are packed in a disposable tube.

There are many different resins on the market which differ in material, chemical formula, packaging, mixing ratio and colour. These are used for many different applications and the correct resin should be used as directed by the specifier depending on consumer preference, performance requirement and installation environment.

Some of the most common resins are Vinylester, Epoxy Acrylate, Polyester, hybrid and pure epoxy – in tube sizes of 300ml, 420ml, 380ml, 410ml, 280ml and 385ml (view the Scell-it range here).

Installing process

A chemical anchor has a resin injected into the hole prior to insertion of a stud. After a set curing time has elapsed this is then used to attach a fixture with a suitable nut. This resin fills any imperfections and irregularities in the drilled hole and so creates an airtight and water proof fit whilst protecting the anchor from corrosion within the base substrate.

Unlike expansion anchors, they have low stress on the substrate and so can be used close to the edge of concrete substrates, or through masonry block, as the non-expanding nature reduces the chances of it cracking the surrounding substrate. Also, slight adjustments can be made during the chemical working time which allows for imperfections in the drilling process.

Other advantages include the ability to provide unlimited setting depths and the ability to apply the load to the entire length of the embedment.

Chemical anchors are considered complicated to install and incorrect fitting can lower their holding capacity. They are also considered more expensive than conventional expansion anchors.

What applications are chemical anchors useful for?

With the correct resin, they can be used for a wide variety of applications including:

Blinds, hinges, gates, boilers, air-conditioners, plumbing fixtures, antenna installation, bracket anchors, railings, anchoring scaffolding, metal gantries, hollow block and joist end plates.

With specialized resins, they can be used for maritime, drinking water and river works.

How to install a chemical anchor

Preparation

Before installation, check the concrete base is compact and strong in order to make sure its class (C) & standard is suitable (min C20). Ensure resin is suitable for the base material and is in date.

The ambient temperature should be within useable range for the resin.

Tools required

> Drill and correct size drill bit > Dust Blower Pump > Cleaning brush > Resin Injection Gun > Resin > Torque wrench

Installation

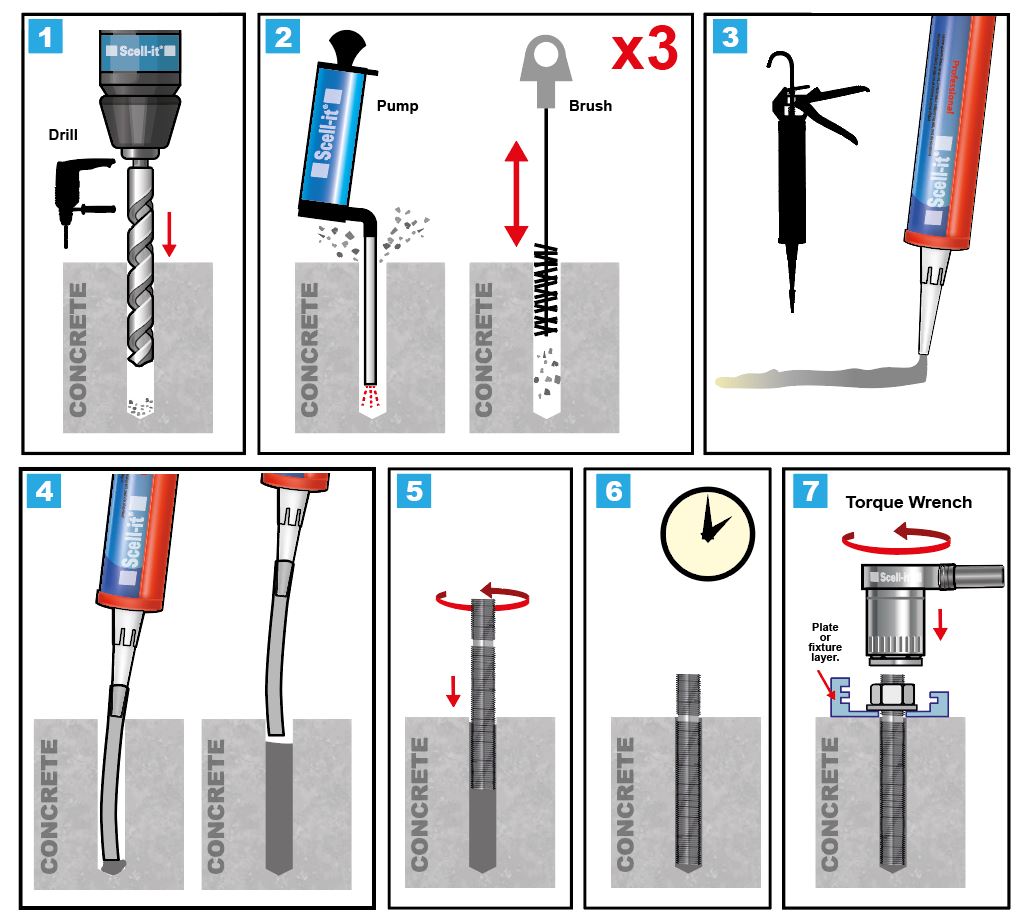

1. Drill the hole

Drilling must follow manufacturer’s recommended values for depth and

diameter of anchor whilst observing the ‘anchor-to-anchor’ and

‘anchor-to-edge’ specified minimum distances.

2. Clean the hole

Remove dust and debris from the hole with a pump and/or a suitably sized brush (preferably a wire brush).

Blow out any debris with the pump then clean out with the brush. Repeat this three times as any debris or dust left will interfere with the setting of the resin.

3. Prepare the resin gun and resin

Place the resin tube inside the injection gun and remove the cap. Fit the nozzle onto the resin.

Extrude about 5 – 10ml of the resin onto a scrap piece of paper until the colour of the mixture becomes evenly grey (this means it has mixed correctly). Release the pressure on the gun using the release button to prevent more resin dripping out.

4. Apply resin to the hole

Fill the hole about half to two thirds full with the resin. Always fill from the bottom upwards to avoid trapping air. If the nozzle does not reach the bottom of the hole then use an appropriate extension tube to achieve this.

5. Insert anchor

Insert and rotate stud/bolt/anchor/rebar/threaded rods into the hole by turning slowly.

6. Hardening and curing

Wait for the recommend time for the resin to cure. Don’t touch until full curing has occurred.

7. Install fixture

Once the curing time is reached, fix the supplied nut & washer with the specified manufacturers max torque.

Additional installation Notes:

The types and ranges of resins on the market means it is crucial to specify and use the correct one.

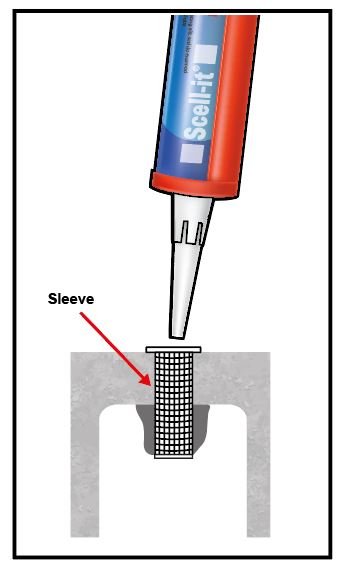

These instructions are a typical example into solid concrete and masonry. Installation into hollow masonry requires a nylon sleeve to be inserted into the drilled hole before filling with resin.

Further help and information on installation can be found in the BS 8539 which was published in 2012 and its purpose is to guide designers, specifiers, manufacturers, suppliers, contractors, installers, and testers of anchors, to ensure correct selection of suitable anchors and a safe and compliant install of them.

See our full range on the product page here or contact Scell-it UK Ltd

on 01785 246539 to discuss supply and delivery.

Chemical anchors are otherwise know as: bonded anchors, chemical studs.

continue reading