Concrete Screwbolts and how to install them.

What are concrete screwbolts

A concrete screwbolt has a cutting thread which cuts into the concrete or masonry when installed. This interlocking between the anchor and the substrate provides a high load carrying capacity.

The concrete is drilled using a hole diameter smaller than the thread diameter to allow the cutting thread of the concrete screwbolt to cut a physical key into the base material. Unlike expansion anchors, this system allows screws to be placed closer together and nearer to an edge. Depth of the cutting thread is proportional to the load capacity of the anchor. The longer the thread – the higher the load.

Screwbolt anchors are usually manufactured from a high strength grade of steel to enable them to cut into hard concrete. This steel is susceptible to hydrogen embrittlement. This can occur when a galvanized product is used in a damp or external environment and has caused failures in the past. The ETA testing for concrete screws now includes a specific test for resisting hydrogen embrittlement, so a screwbolt with an ETA should have no issues with hydrogen embrittlement.

Installation of a concrete screwbolt

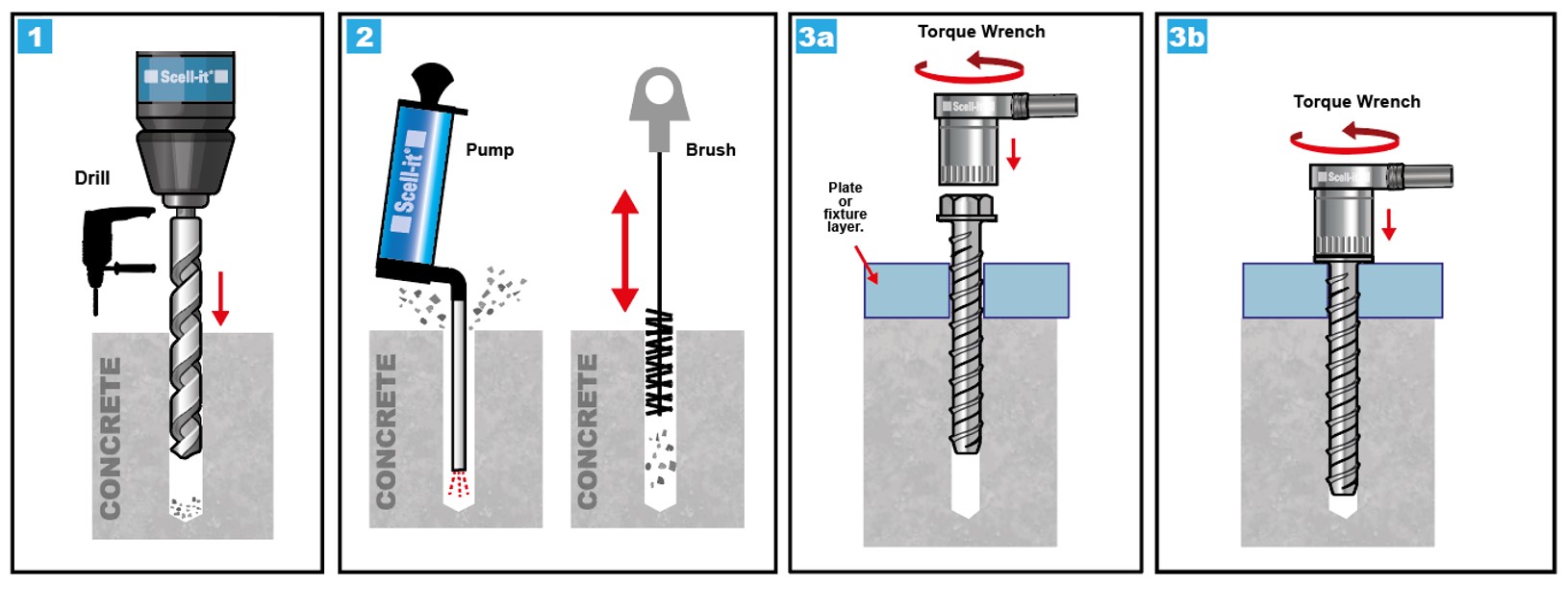

1.Drill the hole

Drill a hole to the correct depth and diameter as recommended by the manufacturer. Hole diameter is normally slightly smaller than the screwbolt to allow for ‘cutting in’ to the substrate. Additionally, the hole should be longer than the screw to provide space for any debris that may collect during installation, preventing it from obstructing the process.

Note: Ensure hole is drilled perpendicular to the surface (with a 5 degree variation). Failure to do so may cause anchor breakage.

2. Clean the hole

Use a wire brush smaller than the diameter of the hole to thoroughly remove dust and debris. Rotate the brush in a circular and up-and-down motion. Blow out dust with an air pump. Repeat this process to guarantee a clean and debris-free hole (fig. 2).

3.Install the anchor

Insert anchor into hole by screwing into base material with a mechanical impact wrench or a torque wrench. Apply pressure to head of bolt to ensure engagement of first thread (fig. 3a). If resistance is encountered when screwing down the bolt, simply unscrew two turns to release trapped dust, and then continue to tighten down. Screw anchor into concrete until the head shoulders firmly with the fixture and stop (fig. 3b). The anchor should not be able to be tightened further. Do not overtighten the screw as this will weaken the installation.

These type of anchors will work even when set in a crack – which might open after the anchor is installed. This means they are suitable to work in cracked or non-cracked concrete. Screwbolt anchors create very little stress in the substrate.

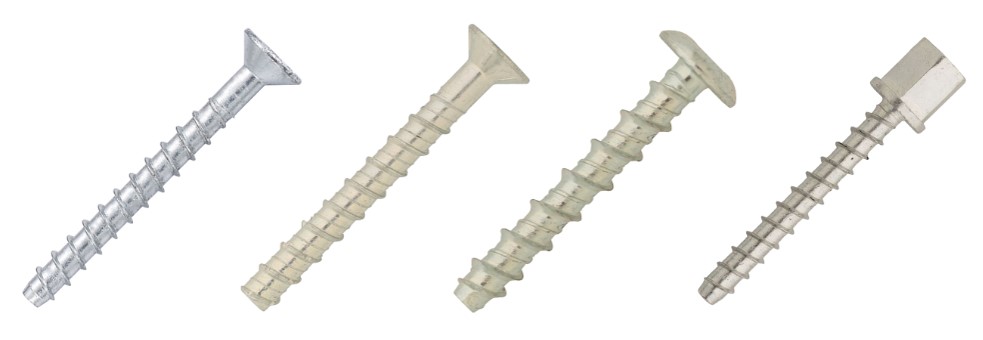

Different heads

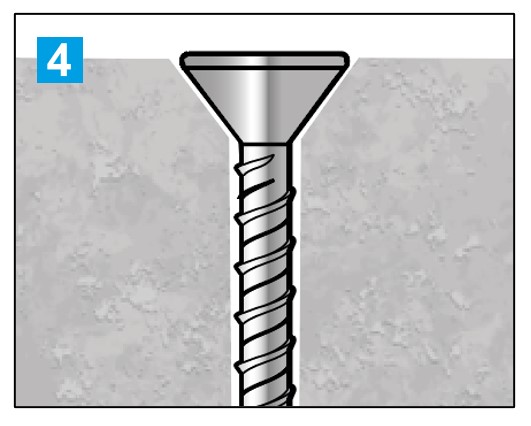

Concrete screwbolts are available in various head styles, such as hexagon, cylindrical and countersunk. The BT-I model features a threaded rod recess, making it ideal for suspended ceiling fixings. These bolts also offer a range of fastener drive types, including slotted, Phillips, and Torx.

When installing countersunk concrete screwbolts – ensure the drilled hole has a suitable hole to allow the fixing to sit flat (fig 4).

These instructions are general guidelines. If you’re unsure, please seek further information and advice.

For more information contact Scell-it UK at sales@scellit.co.uk

continue reading