Guide to the main types of fastener drives

There are many types of screw drive types on the market and this is a quick guide to the most common ones and recommendations for use.

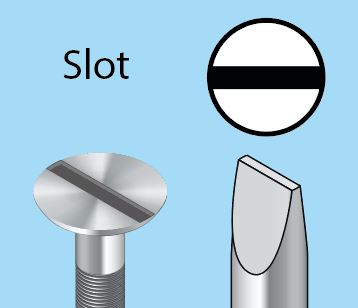

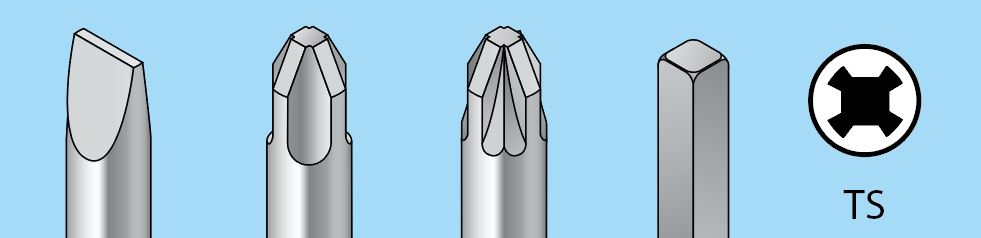

1. Slot or Flathead

This features a single slot on the head of the screw. One of the earliest and cheapest type of drive to make. Is turned by a flat head screwdriver and is easy to use by hand. Can be problematic with a drill or impact driver which tends to slip off the single slot at speed (causing damage) and it is hard to centre the tool on the head quickly.

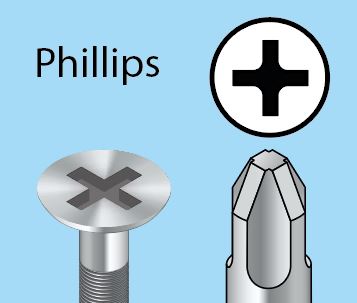

2. Phillips or cross slot

This design has two slots in a crossed recess on the head of the screw and is one of the most common on the market.

Easier to engage with a tool and has more connection which prevents slipping out – however, at high speed the tool will jump off the screw head (cam out). This is believed to be a design feature to prevent overtightening.

Codes & sizes : PH1 (2.5 – 3.0mm), PH2 (3.5 – 5.0mm), PH3 (5.5 – 6.3mm).

3. Torx or Star

This drive has a six pointed ‘star’ shape recessed into the screw head.

It has a good engagement with the tool which prevents slipping or cam out at higher speed and also lowers the need to ‘push down’ when setting.

Popular in automotive and electronics industries. Correct size screwdriver must be used to match size of screw.

Codes & sizes : TX10, TX15, TX20, TX25, TX30, TX40.

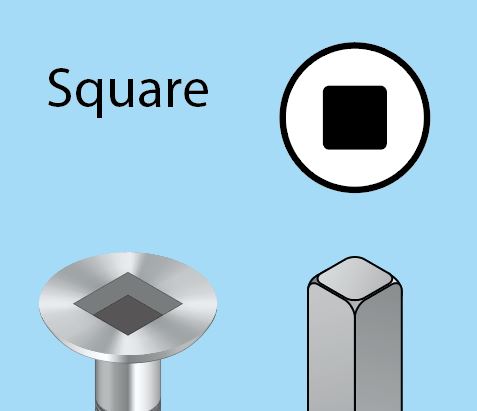

4. Square or Robinson

This design has a square shaped recess in the head. It is easier to insert a tool into and can hold it there very well. This means less slipping and stripping even at high speed but because of this high speed allowance – damage can be caused if over-tightening. Not common in the UK.

Codes & sizes : SQ1, SQ2, SQ3.

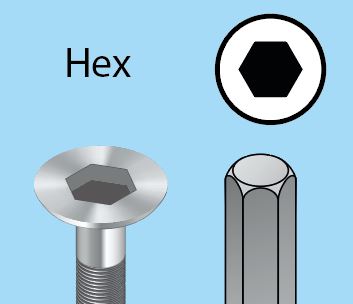

5. Hexagon

This design has a hexagon shaped recess in the head and is popular with flat packed furniture and self-assembly products. It is easy to insert a tool into and can hold it there very well but – like the square drive – damage can be caused if over-tightening.

Codes & sizes : TH10 , TH13, TH17, TH19.

6. Pozidriv

This is shaped like a Phillips head but with extra radial grooves slots at 45°.

Due to these extra slots there is more engagement with the tool and allows for more torque with less cam out and the screw is gripped tightly in the tool. A tapered screwdriver will work on several sizes of pozidriv screws.

Codes & sizes : PZ1 (2.5-3.0mm), PZ2 (3.5-5.0mm), PZ3(5.5 – 6.3mm).

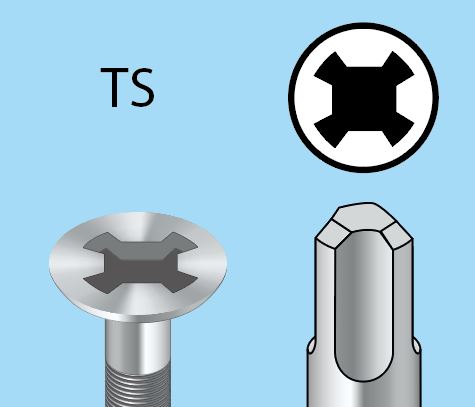

7. The TS – a new design from Scell-it

With all the different types of screw drives it is inevitable that sometimes you end up with the wrong screwdriver for the screws supplied. To prevent this problem Scell-it have invented a brand new universal type of drive. This innovative design can accept four different types of screwdriver head: slotted, cross, Pozidriv or square.

But, it also comes with a unique ‘TS adapter bit’ which – when combined – allows full locking to a TS screw for an easy and controlled screwing action.

Codes & sizes : TS1 (2.5 – 3.0mm), TS2 (3.5 – 5mm), TS3 (5.5 – 6.3mm).

Conclusion

It is obvious that the Pozidriv or torx drives are very popular in the trade and are certainly a quick and timesaving way to install screws. The TS drive design – with its adapter bit – takes this to the next level and is definitely worth trying out on your next job.