Standard Rivet Guide

Scell-it® UK offers the complete range of rivets. These are multiple solutions that can be used on different materials (aluminium, Steel, Stainless steel etc.)

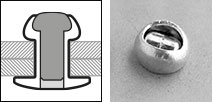

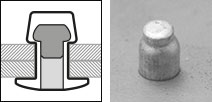

STANDARD

When setting a standard rivet the mandrel is pulled which causes the head to deform and form a bulb behind the assembled pieces.

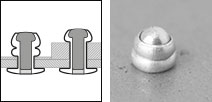

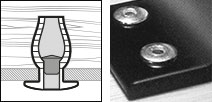

MULTIGRIP

A multigrip rivet forms a double bulb when the mandrel is snapped. The mandrel head remains at the bottom of the rivet enabling a larger clamping capacity. It is suitable for softer materials and is also termed as anti-vibration and weather proof.

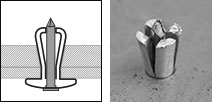

HAMMERDRIVE

When installed with a hammer the mandrel passes through the body of the rivet which splits into 4 pieces. Various combinations of material can be set (wood, plastic, concrete, metal etc.) into a through hole or blind hole.

SEALED

The head of the mandrel is retained inside the rivet body. The body expands to fill the hole enabling it to withstand pressures up to 35 bar. This allows it to be gas and water tight.

GROOVED

The grooved body enables the rivet to hook on to the interior surfaces of the assembled pieces. The grooved rivets provide a strong connection into dense materials like wood and plastics.

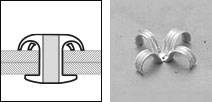

TRIFORM

The triform rivet is constructed to split into 3 parts during setting – preventing the material from being damaged. Ideal for plastic and soft materials.

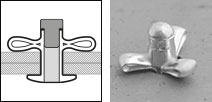

PEELED

When set – the peeled rivet splits into 4 ‘petals’ which clamp the material and spreads the load over a wide area. Ideal for soft or thin material.

Applications

Materials

ALUMINIUM

The most economical material. Easy to set with minimum of tool requirements. Our standard grade is 3.5mg.

STEEL

Used for the best technical performance in non-corrosive environments.

STAINLESS STEEL

Grade A2 or A4. Choose the corrosion resistance that best suits your application with Scell-it stainless steel.

Type of Head

DOME

DOMEThe most common rivet head type. Suitable for most situations.

LARGE

LARGEThe “large” head reinforces the application hole and allows the assembly of soft components such as plastic and wood on metal. It distributes the force over a larger surface.

COUNTERSUNK

COUNTERSUNKThe “countersunk” head offers an optimal, concealed surface finish and perfect aerodynamics without any air resistance.