The advantages of brushless motors

How does a standard DC motor work?

A standard DC motor converts electrical power into mechanical motion. It does this by applying electrical current to windings to create a magnet force which reacts against another fixed magnetic force to create movement. This movement is fixed on a rotor, connected to a shaft, to create a rotating motion needed for movement (such as a ‘drill spinning’ or ‘wheels turning’).

What are the differences between brushed and brushless motors.

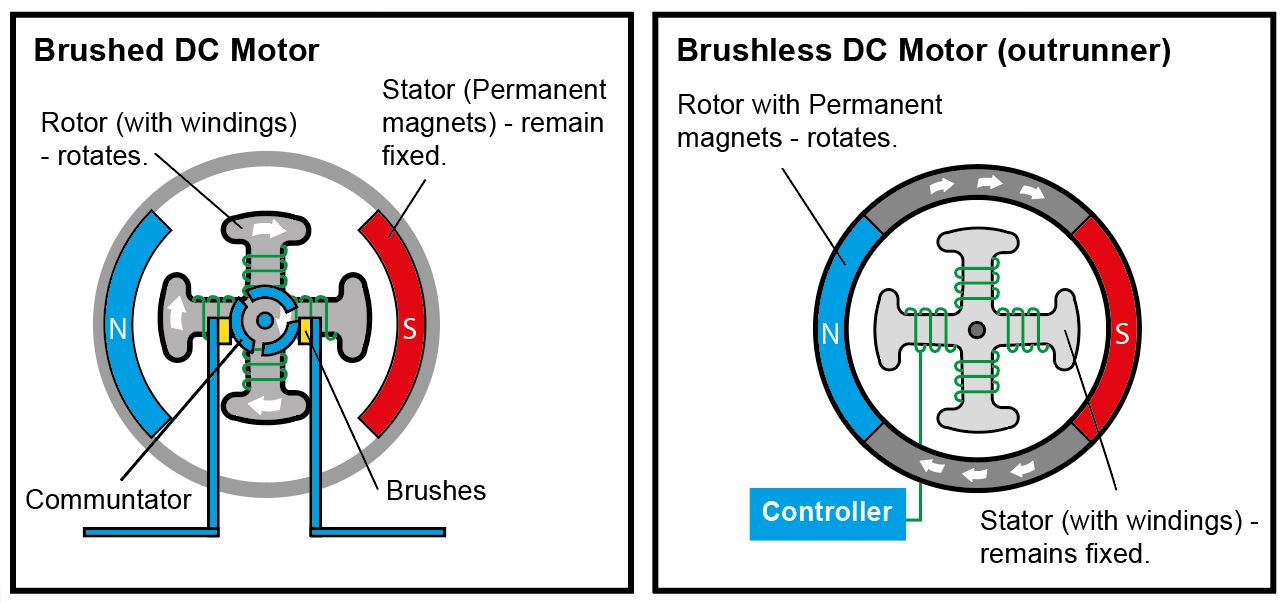

A brushed motor uses a commutator to switch the polarity (North & South) of the magnetic field generated around the wound component of the motor (rotor). This reacts with the fixed polarity of the stationery magnets (stator) around the outside to create rotation. The ‘brushes’ are the electrical contacts between the commutator and the motor’s windings.

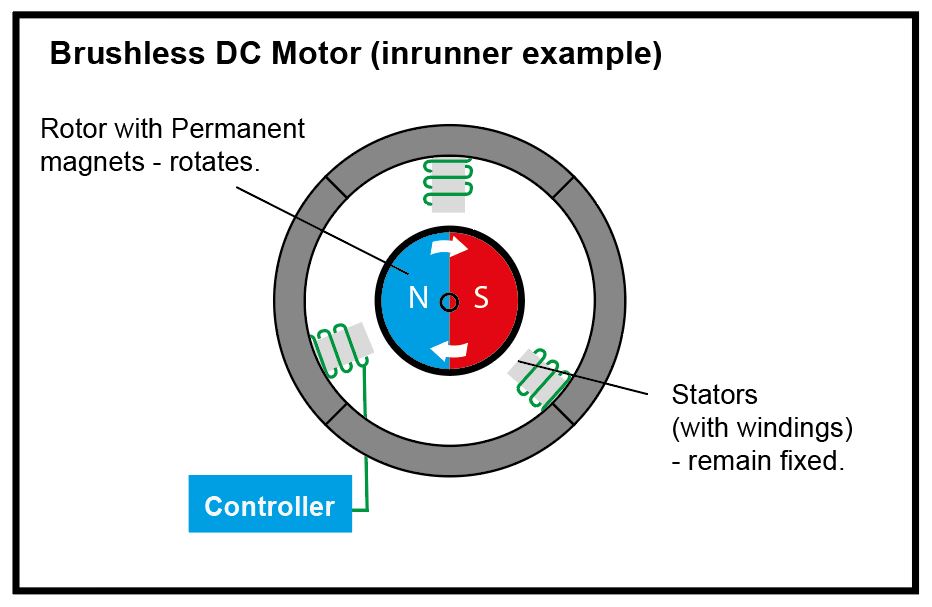

A brushless motor also has a rotor and a stator but current is flowing through the windings of the stator. The rotor is made of permanent magnets. No brushes are needed as the commutation is an electrical process driven by a controller. By using a sensor, the controller estimates the position of the rotor and decides when to switch the current and thus energises the correct stator winding. Note: the rotor that’s made of permanent magnets can be located either on the inside of the motor (inrunner BLDC motor) or on the outside (outrunner BLDC motor).

Advantages of Brushless motors.

– The biggest advantage of brushless motors is the lack of brushes that get worn and need replacing. This also means less unwanted friction and heat – resulting in better performance, reliability and less maintenance.

– The mechanical commutation in brushed motors is less efficient and can lead to power loss. In fact, brushed motors are estimated to be about 85% efficient but brushless is considered to be nearer 90% efficient. This means more force is turned into rotation rather than heat.

– The sparks created during current switching on brushed motors can cause a high level of electronic noise.

– Brushless motors tend to be smaller and more lightweight which makes it ideal for use in portable electronics and wireless devices of different sizes.

– They also switch currents at a higher frequency which allows the motor to maintain a high torque and run smoothly at both low and high speeds.

All in all, ‘brushless motors’ provide increased durability, more noise reduction and uses less energy.

But – this extra advantage of the brushless motor can come at an extra cost – mainly because of the extra parts needed, such as the controller and sensor. That is why brushless motors are usually found on higher quality tools and is supplied on almost all Scell-it UK power tools – even the low cost E-00 range.

For more information on the Scell-it UK range of setting tools go to our tool range page here.