Through bolts and how to install them.

What are through bolts?

Through bolts are anchors which go through two or more layers and binds them together

(e.g. fastens a metal plate onto concrete).

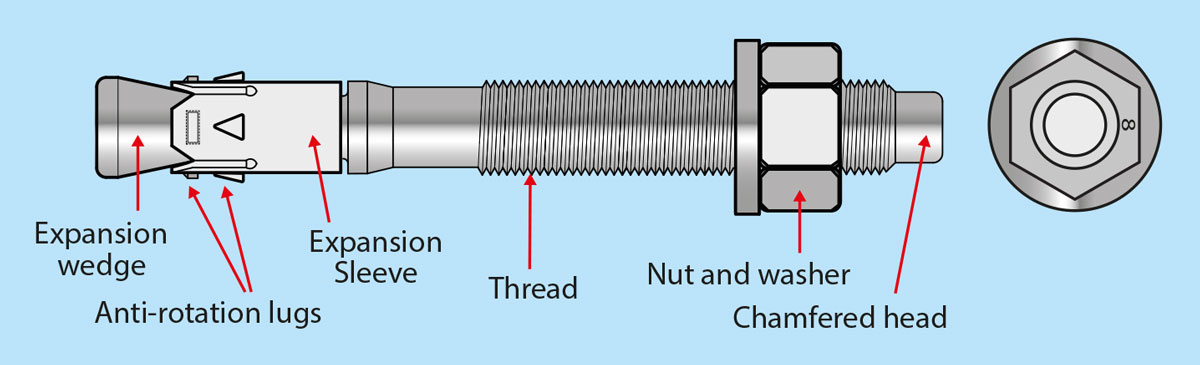

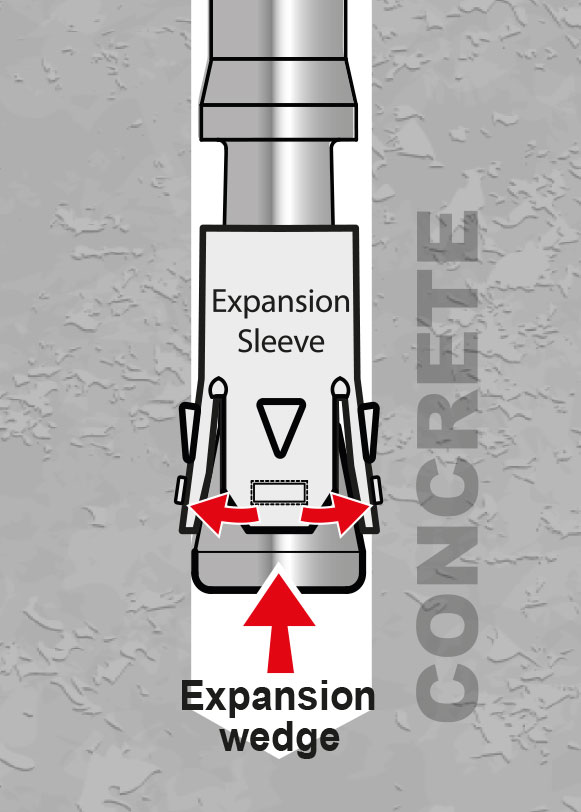

It is made up of :

– expansion sleeve – Stainless Steel or B2P Steel

– a thread

– a nut (G8) and washer (Form A).

It works by using friction caused during installation when the sleeve expands as it

It works by using friction caused during installation when the sleeve expands as it

travels up the expansion wedge, which grips the base material. Anti-rotation lugs

on the sleeve prevent the through bolt rotating when tightening.

Through bolts are a heavy-duty high performance anchors that are relatively priced.

What applications are through bolts useful for?

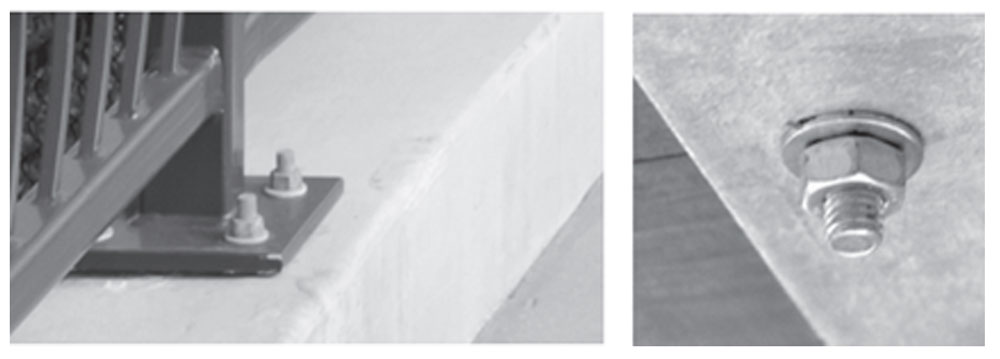

Through bolts are suited to through-fix installations in cracked or non-cracked concrete for medium to heavy loads.

It is great for bolting awkward fixtures in place without the need for marking out, removal and repositioning.

Ideal for fixing brackets, cladding, restraints, racking, handrails, fabricated stairwells and industrial doors.

Through bolts are not suitable for Brickwork or Blockwork.

How to install a through bolt

Before installation, check the concrete base is compact and strong in order to make sure its class (C) & standard is suitable (min C20).

In cold conditions (below 0 ºC), make sure water does not seep into the hole, as this could cause subsequent cracks in the concrete, due to ice pressure.

Tools required:

> Drill and correct size drill bit > Dust Blower Pump > Cleaning brush > Hammer > Torque Wrench

Installation

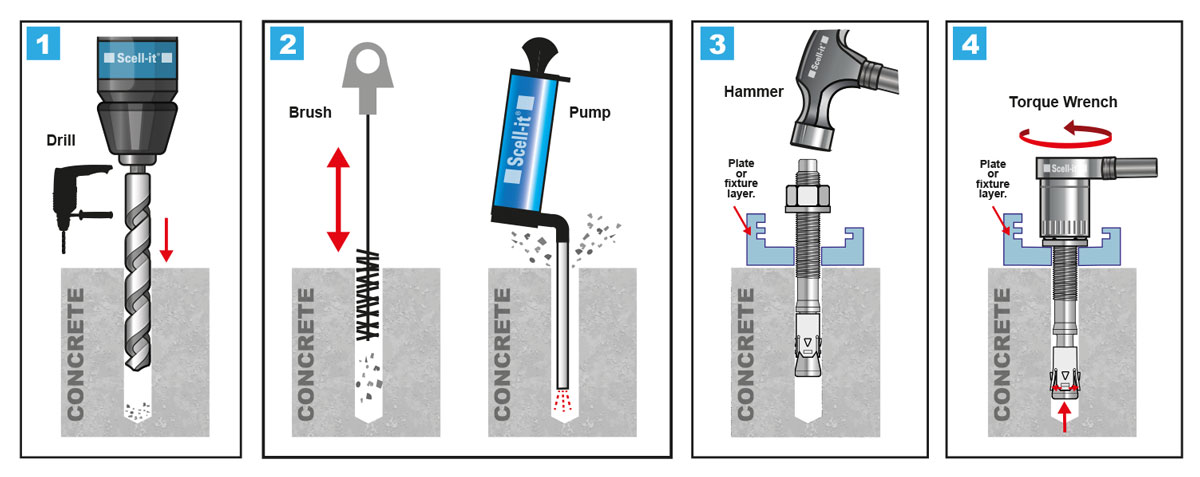

1. Drill the hole

Drilling must follow manufacturer’s recommended values for depth and

diameter of anchor whilst observing the ‘anchor-to-anchor’ and

‘anchor-to-edge’ specified minimum distances.

2. Clean the hole

Remove dust and debris from the hole with a pump and/or a suitably sized brush (preferably a wire brush).

This is to prevent premature anchoring of the through bolt.

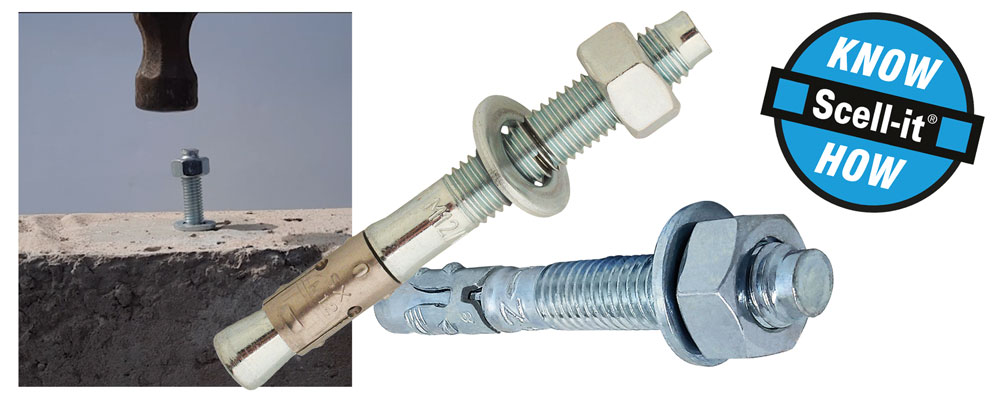

3. Place the anchor

Place the anchor through the fixture/material to be fixed and into the hole, at the correct angle. Observe the correct embedment depth according to the manufacturer’s recommended values.

Set the nut just below the head and use a hammer to gently tap the chamfered head of the bolt until the nut and washer sit flush with the fixture (be careful not to deform the anchor when striking it).

Do not apply any intermediate layer between the material to be fixed and the washer, such as sealing products.

4. Apply torque

Tighten the anchor with a torque wrench. Note: It is important that it is set to the manufacturer’s recommended torque setting. This will create the clamping force required to hold the fixing and should not be overtightened.

Additional installation Notes:

As with all expansion anchors – Through bolts suffer from load relaxation – when you have torqued it up correctly it will relax. The stress in the bolt will be dissipated into the substrate over a given period of time.

ETA approved anchors take into account this drop in tension. At Scell-it UK – non-approved anchors are tested thoroughly with a pull-tester and this load relaxation is checked.

It is vital that torque recommended settings are adhered to. This is because it is easy to overtighten through bolts and over-stress the anchor. If you under torque the through bolt you run the risk of the fixture moving after load relaxation.

When drilling near any reinforcement areas, special care must be taken to avoid damaging them. If drilling is aborted because a reinforcement area has been encountered, it is advisable to drill a new hole at a minimum distance of at least twice the aborted drill hole diameter. The abandoned hole must be sealed with either a resin or concrete before setting the next anchor.

Further help and information on installation can be found in the BS 8539 which was published in 2012 and its purpose is to guide designers, specifiers, manufacturers, suppliers, contractors, installers, and testers of anchors, to ensure correct selection of suitable anchors and a safe and compliant install of them.

Testing a Through Bolt

Scell-it UK always test non-ETA through bolts and even provide an on-site testing service for Thorough bolt anchors for customers.

This is achieved with the use of the latest ‘Staht’ pull-tester. This inexpensive tool is available to buy and provides indisputable digital proof of the holding force of an anchor.

Test procedure

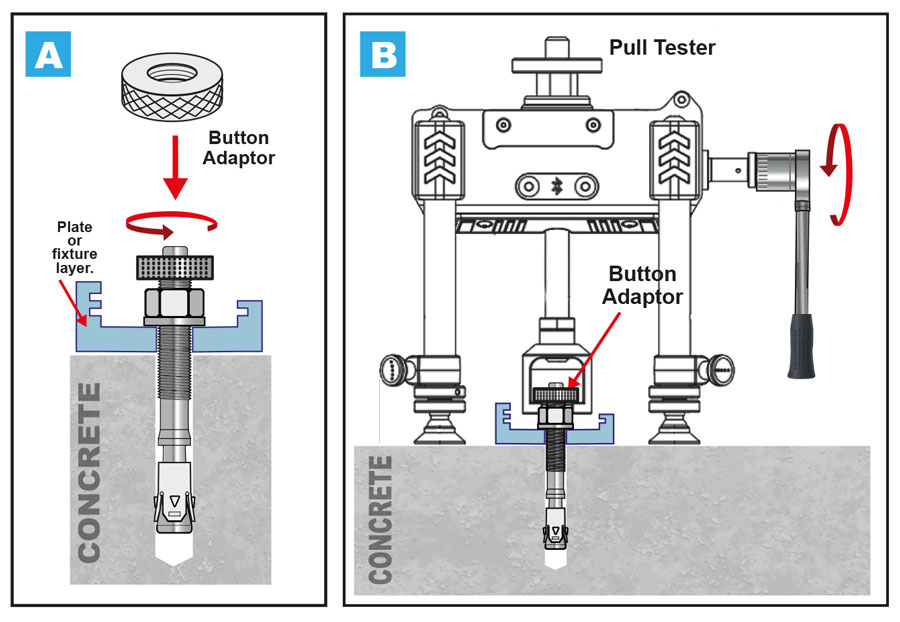

- After anchor is installed – if sufficient thread is exposed, screw on the correct sized threaded button adaptor. If more thread is required – unscrew the nut and washer . (see fig. A)

- The pull test unit is set up above the fixing and the adaptor jaw is set around the threaded adaptor (see fig. B).

- Pull test is set up on the tester app and pull-test is commenced by winding up the handle.

- Pressure is applied to the anchor manufacturer’s recommended load and time.

- Pressure is released and pull test unit removed. Retighten the bolt if testing has loosened it slightly.

- Tester app will generate a digitally signed report to confirm a PASS or FAIL.

Scell-it UK quality through bolts

All Scell-it through bolts are ETA approved or pull-tested by Scell-it

internally with digitally signed certification.

A Digital Coating Thickness Gauge is used to carry out further tests.

This provides a reading – in microns – and ensures the fixing

coating is to the correct standard.

See our full range on the product page here or contact Scell-it UK Ltd

on 01785 246539 to discuss supply and delivery.

Through bolts are otherwise known as:

Throughbolt, throughbolts, Zinc Throughbolts, Galvanised Throughbolts, Stainless Steel Throughbolts, Masonry throughbolts, Stone throughbolts, Concrete Throughbolts, Through bolt anchors, Throughbolt Masonry Anchors, Anchor throughbolts, TB7.

continue reading